Adopt a proper procedure to maintain flawless inventory. Such a situation is better said than done, especialy in a retail organization where the movement of goods is rapid and frequent. Before the advent of the computer-based inventory control systems, stocks were tabulated manually. Stock cards kept track of goods received and goods sold or delivered. Check the stock card against the physical stock. It would be done either biannually or annually. The whole organization would come to a standstill until the stocks were verified.

After the perpetual inventory systems were introduced, such manual tabulating became obsolete. The system showed the receivables and stock in hand at the tap of a key. Still, there was no guarantee that both the physical stock in hand and the books always matched.

Keeping track of such rapid movements would need an efficient computer-generated system. Still, there are many a slip between the cup and the lip, and when and if physical stocks are taken, there can be a discrepancy between the records and the goods in hand. Invariably what could happen would be the recorded quantity would be more than the physical stock. This is inventory shrinkage.

The following are 7 ways to reduce inventory shrinkage.

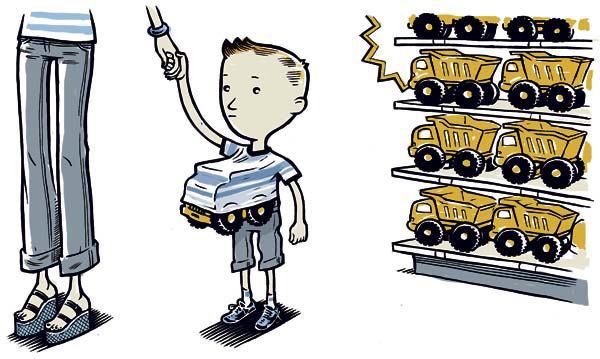

#1. Stop customer theft

This is a major issue encounter by all retailers. There are gangs of customers who would enter a large retail store with the primary aim of pilfering items. All precautions like security tags, scanners at entry, and exit points are needed. Beefed up the security and at optimum efficiency at all times.

#2. Stop employee theft

Employees should not be allowed to pilfer stocks at any time, and proper surveillance should be in place. Tight security controls are required at all points within and exit to ensure no leverage is given.

#3. Check errors in scanning

Regularly and randomly check the scanning equipment for flaws. Ensure that the system has professional support and service. If there are any flaws, it will open to flood gates, and the management would not be aware until the horses have bolted. The systems for scanning would need checking more often than not.

#4. Delegate and designate responsibilities

Delegate and designate areas of responsibilities that would keep every staff member on his or her toes and also ensure that they are responsible for reducing inventory shrinkage. Once employees know their territories of responsibilities, they would endure reducing inventory shrinkage.

#5. Tabulate all damaged stock

Damaged stocks are part and parcel of any type of business which should be kept at the minimum. Employees should be aware that it is their responsibility, and also, if such incidents occur, they should be immediately informed. The Warehouse supervisor should authenticate the fact and remove such items from the system. Prevent damaged stocks and hence remove from physical stocks and from the records too.

#6. The loss at the point of acceptance

At the point of acceptance of goods, check every packing list thoroughly for any discrepancies either due to pilferage or human error. There would not be an ideal situation, but with high-security systems in place, it would be able to reduce inventory shrinkage.

There should be no flaw and discrepancies when Stocks ordered, received, and taken into the perpetual inventory system. Discrepancies could occur not always due to pilferages but due to human error too.

#7. Take random stock checks

The only way to check and reduce inventory shrinkage would be to take random stock checks of one or more items. It is only when you have the quantity of physical stock available that you could cross-check it with the system balances. Such random stock checks would place even the staff on a leash and ensure that they are kept on their toes at all times.

Conclusion:

A penny saved is a penny earned. In that context, every endeavor should reduce inventory shrinkage. It is difficult to eliminate it, but control it to be at the minimum.

Start using ZapInventory today

Start using ZapInventory today