What is Supply Chain Optimization? – Everything you need to know

Do you know how does supply chain optimization can have a strong impact on the market situation?

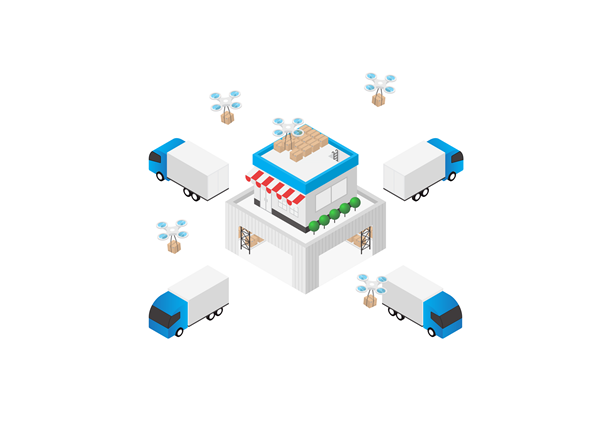

In this short article, we will have an overview of Supply Chain Management and how it is actually structured.

So, let us start by knowing what is Supply Chain Optimization

Now let us go deep into the subject and know about the 5 components of the Global Supply Chain, which are Plan, Source, Make, Deliver, and Return.

Components of Supply Chain Optimization

- Plan – Here we start to plan all our activities to develop a Product. In this step, the design of the product is finalized according to the scope of supply prepared for the client. Then the Manufacturing method is finalized, and according to it, the procurement calendar is prepared as of, which material or instruments are needed to purchase at which stage of the production, etc. then after studying all the factors we come up with the final delivery date of the product.

- Source – Sourcing is an important step in the supply chain. After the planning is done, then we start the purchasing activities which include the purchase of raw materials, some essential instruments, and all the necessary devices required for the production, etc.

- Make – By procuring all the necessary things, then only the manufacturing is started. The production must be in line with the plan as it has the highest lead time. And that is why Sourcing is very much important in the overall process.

- Deliver – after the final product is ready, then comes the delivery part, which is the final frontier for a vendor as well as the client. For the Delivery of the product, we need to have the strong logistical support to transport the product to its destination.

- Return – this is also called Reverse Logistics. It happens when the client is not satisfied with the product and wants to have some modification, or maybe in some cases client would want a replacement of the product. Most of the time, it is impractical for such returns, but there is a sheer possibility that the client can even reject the final product and sent it back to the vendor.

Now let us have a look at the types of supply chain management models –

Supply Chain Models

There are 6 Supply chain models namely –

- Continuous Flow Model – this supply chain model works for the manufacturers who have standard production or who do not have any customized products and develop only one kind of product. It is one of the most traditional supply chain models which is suitable for high-demand products in the market.

- Fast Chain Model – this model is most suitable to those manufacturers, who go with the flow of trends and manufacture the product which will suit the current needs of the customers, though it has a short life span.

- Efficient Chain Model – in this model, end-to-end efficiency is of utmost importance. Such manufacturers believe in the high competition market to increase productivity.

- Custom Configured Model – here the focus is on developing customized products according to the need of the customer, irrespective of the trend and tradition. Here the product may be either developed based on an efficient model or a hybrid model.

- Agile Model – this is one of its kind of supply chain models, where the customer is given the authority to have a special product being developed for them. This mostly focuses on the ability of the supply chain to be solid, even when there is no market movement.

- Flexible model – Flexible Supply Chain model allows the business freedom, to meet the demand of the market and schedule the procedure. This model is so flexible that it can be operated or shut down easily without much effort.

So, this is how the global supply chain works. In this short article, we have gone through the basic information, but it is a vast field of operation which needs more precise content to understand better.

So, in our next article, we would be going much deeper into the said domain and know some other important aspects of Supply Chain Management in the global market.

Start using ZapInventory today

Start using ZapInventory today