Material Requirements Planning (MRP) is a method that calculates the number of materials required for production. One of the primary material requirements planning objective is ensuring that there is a supply of raw materials until the end of the production line.

According to American Production and Control Society (APICS), “MRP constitutes a set of techniques that use bill of material, inventory data, and the master production schedule to calculate requirements for materials.”

It uses the master production schedule to derive the number of raw materials, components/ parts, assemblies, and sub-assemblies. It develops a chart of these requirements and the timing of order-placements.

The material requirements planning objective is based on logical ideas, procedures, and rules that break down the production process.

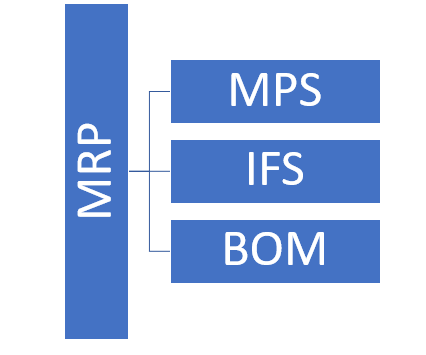

Inputs for Material Requirements Planning (MRP)

The MRP system has three kinds of inputs:

- Master Production Schedule (MPS)

- Inventory Status File (ISF)

- Bill of Materials (BOM)

MRP gathers data about order release requirements, order rescheduling and planned orders from these inputs.

1) Master Production Schedule:

It is a collection of quantities for every produced item indicating its stage. MPS is formulated from customer’s orders or demand forecasts. The MPS system’s input is then broken down into specific component needs. MPS is the critical component that supports the MRP, so many companies go for a trial run to check the compatibility of MPS with MRP.

2) Inventory Status File (ISF):

Every item in the inventory has a file that gives complete and up to date information. It contains details about on-hand quantities, requirements, scheduled delivery and re-order data. It also includes information such as safety stock levels, scrap allowances and lead times.

3) Bill of Materials (BOM):

BOM contains the details of the end product like the sub-components, their build-up order and their quantity in each product. In addition, the product design documents, workflow analysis, and other manufacturing information is the source of information for the BOM.

Enable end-to-end production planning and manufacturing control by creating Bill of Materials (BOM) with ZapInventory.

Sign up for free!

Objectives of Material Requirements Planning (MRP):

- One of the primary material requirements planning objective is that it reduces inventory. It accurately determines the required materials for every product. As a result, it helps the company procure materials as and when needed and avoids excessive build-up.

- It identifies materials quantities, timings, avail-abilities, procurement and actions required to meet deadlines. It aids in avoiding delay in production and indicates the due date of the customer’s job order.

- MRP enables the firm to give realistic delivery dates to the customers. Therefore, even the slightest delay can be relayed to the customer and effective measures can be taken.

- One of the best material requirements planning objectives is that it improves coordination among the employees. It helps in achieving an uninterrupted flow of inventory through the production line. MRP strategically enhances the efficiency of the production system.

- It guarantees that the inventory level is at its optimum levels. Additionally, it ensures that the material and product is ready for production and thereby matching demand and supply.

- It is a priority system that throws up a red alert as soon as the safety levels are breached. Subsequently, if there is a missing component, the MRP system will reschedule it to another time.

MRP is a capable system that will aid a manufacturing company in keeping optimum inventory levels. Also, it makes way for efficient working capital and improves factory operational efficiency by better use of resources.

FAQs on Material Requirements Planning (MRP)

Why Material Requirements Planning is important?

Who uses MRP?

What are the three main goals of an MRP system?

1) Ensure the right material is available for production and finished goods are available for delivery to the customers.

2) Enable end-to-end production planning and manufacturing control by maintaining the required stock levels.

3) Plan manufacturing and managing production priorities.

—————————————————————————————-

Related: Inventory Management Tool: How it can help Manufacturing Companies?

Start using ZapInventory today

Start using ZapInventory today