Inventory management can be define as the management of stock of goods. This stock is used as a buffer of goods which helps in meeting sudden rise or fall in demand. It can be used to store different types of goods such as Raw materials, work in process goods and even the finished goods. Maintaining inventory is always a good practice for retail and production companies especially when the demand for goods can rise and fall anytime.

Managing these inventories is not a simple task and requires certain strategies and techniques. Inventory management deals with maintaining the records of flow of the goods in and out of inventory. The main aim of Inventory management is to keep the inventory organized and not let the goods overflow or drain.

Different Ways In Which Effective Inventory Management Helps Your Business:

The most common method is the year-end account balancing for inventory, but this can be ineffective and there are better ways to be found.

1. FIFO LIFO

These are the two main principles of inventory management. A FIFO (First In First Out) method says that the stock or product that gets first inside the inventory should be First to go out of the inventory. This method is most effective when goods are perishable and have chances of turning into waste if kept for a longer duration.

LIFO (Last In First Out) method says that the goods that get in last have to be the first ones to get out of the inventory. This method can used when goods are non-perishable and the demand for goods is high enough.

2. Keeping Regular track of flow through Inventory

Instead of depending on the yearly or half-yearly analysis and reconciliation of inventory it is better practice to keep regular track of the flow of goods and their costs. This can help in statistical analysis of flow of material in and out of the inventory. Cycle counting of physical inventory can help fulfill the purpose; Cycle counting means a weekly or monthly counting of physical inventory to match with the statistics stored.

3. Set Limit Levels for stocking products

Setting the minimum and maximum levels for storing every kind of material can help in keeping inventory more organized and avoiding the overflow or draining of the goods. These levels should be set depending on the through-out demand for each product separately.

Two scenarios should be consider while setting the limits. First, taking the demand of the product in consideration, and then set the minimum level in such a way that there should not a shortage of goods when a sudden rise in demand takes place. The second Scenario should be considered is that particular product should not take all the space in inventory and sit there for the longer duration. This would make the inventory bulky; setting the maximum level will help to avoid this problem.

4. Classify your items

Every product needs to paid attention in different ways. Some products need more attention than the others depending on their costing and sales. You can classify the products into categories like;

- Product with high cost and lesser sales

- Product with moderate cost and moderate sales

- Product with lesser cost but higher selling rates

Items with higher costs require special care because their damage can lead to major losses. So While items with lesser cost and higher demand won’t need extra attention as they won’t remain for a longer time in the inventory.

5. Use smart ways for Inventory management

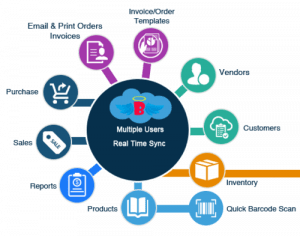

There are different components available that can help you in managing the inventory. Barcode scanners, mobile computers, inventory software are some of the components. Our Inventory management software can save your time and help you reduce your efforts. The statistics dashboard provided will help you in keeping track of your inventory in real-time.

In conclusion, use smart and strategic management methods for managing your inventory and save your money. So that maximizing the timely supply of goods and products to customers and reducing the total cost of inventory is the most effective outcome of good inventory management system.

Start using ZapInventory today

Start using ZapInventory today

3 Comments

Taylor Bishop

Thanks for this advice for inventory management. It’s good to know that you should try to keep a regular track of the flow of the material in and out of the inventory. This sounds helpful if it gives you an idea when certain materials need to be ordered again.