Coronavirus is spreading at a rapid pace. It has already created a massive impact on world economy. Along with that, it is important to take a look at the way on how the coronavirus will create a negative impact on supply chain management as well.

It is better to have a basic overall understanding on how the coronavirus will be able to create an impact on supply chain management. Along with that, you will be able to figure out how to overcome the negative consequences that you will have to deal with.

The impact created by coronavirus on supply chain

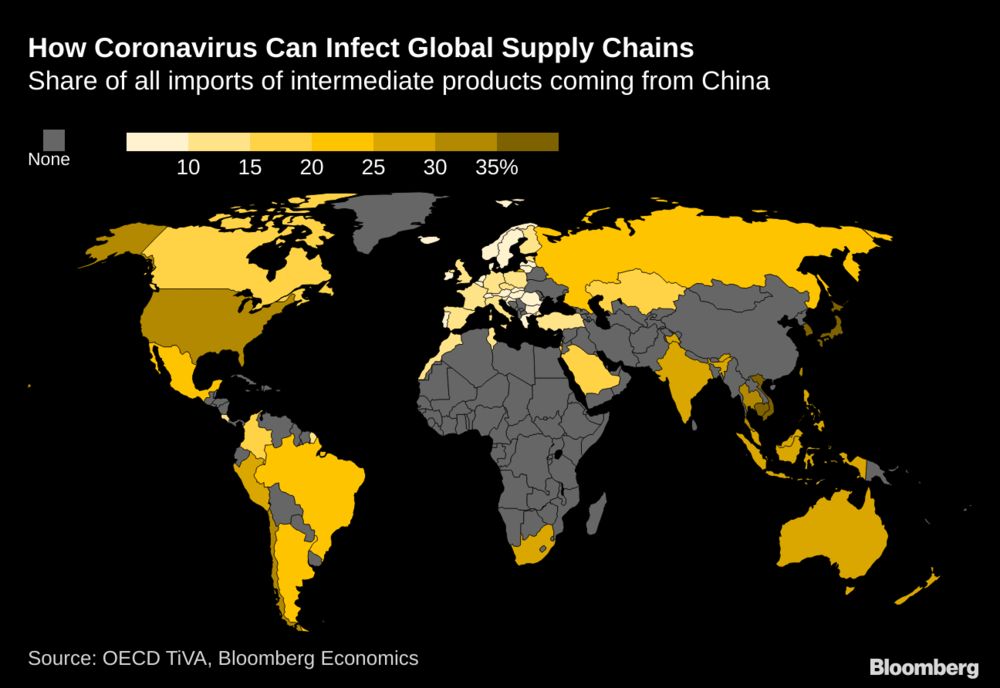

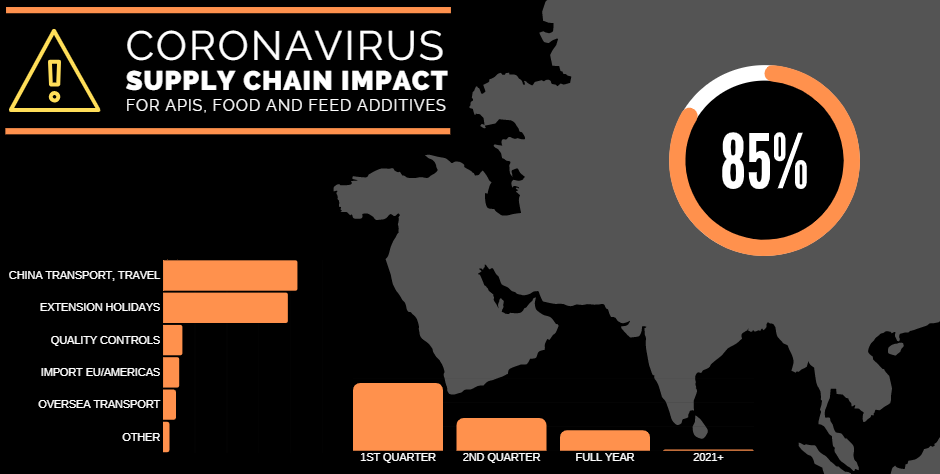

As mentioned earlier, coronavirus has been able to create a massive global disruption. It is also creating a strong negative impact on the end to end global supply chain as well. Due to the same reason, there is a high possibility for a supply chain disruption to take place in the future. In order to get a better understanding about this, you can take a look at the products that you are using on a daily basis.

Every single product that you use will go through numerous stages in supply chain before it reaches you. For example, it is initially in the raw material stage. Then it gets to manufacturing stage, packaging stage, transportation stage and then the distribution stage. The journey taken by the product includes rail, ocean, air and road before it comes to your home. Software like ZapERP can help you to perform some of these stages without getting contact with out side world, you can sync your orders, Order essentials from your vendor to sell, fulfill your orders, contact your customers about delay in shipment due to this crises.

Each element that we discussed above is belonging to the complex network of supply chain. This network is connected globally. Along with that in mind, you need to take a look at the negative impact that the coronavirus has been able to create in the world that we live in.

Imagine what would happen when the coronavirus creates an impact on every single node that is associated with supply chain. Then you will not be able to get the supplies that you need to cater to the demand. Fixing the problem will not be an easy thing to do as well. That’s because you will have to pay individual attention to each and every node and work on how to fix them accordingly.

In order to get a better understanding about this, you need to take a look at toilet paper as an example. The demand for toilet paper has increased significantly. In supermarkets, the shelves containing toilet paper are empty. That’s not just because production of toilet paper has come to a halt. Numerous other constraints have created an impact on it.

Raw material is needed for the production of toilet paper. This raw material is stored in a sophisticated network. The network is affected with coronavirus. On the other hand, there are no drivers to transport raw materials to the factories that manufacture toilet paper. There is no possibility to get the already manufactured toilet paper out of the factories as well. As you can see, this has given life to a series of issues. It is quite a difficult task to solve these issues and come up with effective solutions. Therefore, we will be able to see the shortage for toilet paper in the upcoming months as well.

We are still not too sure on how the coronavirus will behave in next couple of months. Based on that, we can expect things to improve or get further trouble.

How long will it take for supply chain to get disrupted?

When you take a look at the situation 8 weeks ago, you will not be able to find any such issue. In fact, the disruption was there in China, but not in other parts of the world. However, companies that are sourcing products made in China has to experience the negative impact. Numerous suppliers based in China went ahead with unplanned shutdowns because of the threat created by the virus. Along with that, we were able to see a chain reaction taking place all around the world. As of now, we are seeing the negative effects by that chain reaction.

Coronavirus has now become a global pandemic. It is creating a negative impact on the financial markets as well. In the meantime, we will be able to see it creating a further impact on the supply chain in the long run. As per the current trends, we will be able to see a short term impact on the global economy. We are still too early to predict how it will take place in future. We just need to keep our fingers crossed and see how things will change along with time.

What long term changes will we have to face?

Based on the current factors, there is a possibility to predict some of the long term changes that will take place along with coronavirus as well. If we can take control over coronavirus in the next couple of weeks, we will be able to see the global supply chain returning back to normal within a period of around two to three months. Based on what we can see in China, there is a possibility to take control over coronavirus. Companies in China have started as soon as they have taken control over the virus.

It is up to the other countries in the world to take a look at this and make sure that appropriate actions are taken. Along with that, companies will be able to recover quickly and contribute towards global supply chain. This will be a good lesson for you as well. That’s because you will be able to understand how you should be behaving when such a global pandemic strikes your supply chain.

Start using ZapInventory today

Start using ZapInventory today

1 Comment